Принцип работы вакуумной присоски

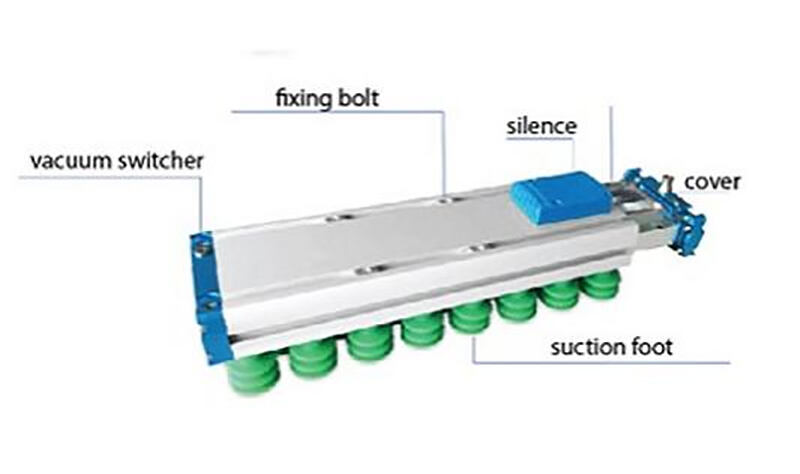

Насосная нога

Присоски являются соединительным компонентом между изделием и вакуумной системой. Характеристики выбранных присосок оказывают основное влияние на функционирование всей вакуумной системы.

Основной принцип работы вакуумной присоски

1. Как деталь吸附ируется на присоске?

По сравнению с окружающей средой вакуумной системы, между присоской и изделием образуется область низкого давления (вакуум).

Из-за разницы давлений изделие прижимается к присоске.

δp = p1 – p2.

Сила пропорциональна разнице давлений и эффективной площади, F~ Δp и F~ A à F = Δp x A.

2. Важные характеристики вакуумной присоски

Внутренний объем: внутренний объем присоски, который откачивается, непосредственно влияет на время нагнетания.

Малый радиус кривизны: малый радиус изделия, которое может быть захвачено присоской.

Ход уплотнительной губки: относится к сжатому расстоянию после создания вакуума в присоске. Он непосредственно влияет на относительное движение уплотнительной губки.

Ход присоски: эффект подъема при работе присоски.

Классификация присосок

Распространенные присоски включают плоские присоски, рифленые присоски, эллиптические присоски и специальные присоски

1. Плоские присоски: высокая точность позиционирования; Компактный дизайн и малый внутренний объем позволяют минимизировать время захвата; Достигается высокая боковая сила; На плоской поверхности детали широкая уплотнительная губка обладает хорошими герметизирующими свойствами; Обеспечивается хорошая стабильность при захвате детали; Встроенная конструкция присосок большого диаметра может обеспечить высокую силу всасывания (например, присоски с дисковой конструкцией); Поддержка снизу; Большой и эффективный диаметр присоски; Существует множество видов материалов для присосок. Типичная область применения присосок с частотным регулированием: перемещение плоских или слегка вогнутых деталей с плоской или слегка шероховатой поверхностью, таких как металлические листы, картонные коробки, стеклянные пластины, пластиковые детали и деревянные панели.

2. Характеристики гофрированных присосок: 1.5-кратная, 2.5-кратная и 3.5-кратная гофра; Хорошая адаптация к неровной поверхности; Присутствует подъемный эффект при захвате детали; Компенсация различных высот; Деликатное захватывание хрупких деталей; Мягкая нижняя рipples; Ручка и верхняя часть присоски имеют высокую твердость; Мягкое и адаптивное коническое уплотнительное кольцо; Нижняя опора; Существует множество материалов для присосок. Типичные области применения гофрированных присосок: обработка чашеобразных и неровных деталей, таких как автомобильные металлические пластины, картон, пластиковые детали, алюминиевая фольга/термопластические упаковочные изделия и электронные компоненты.

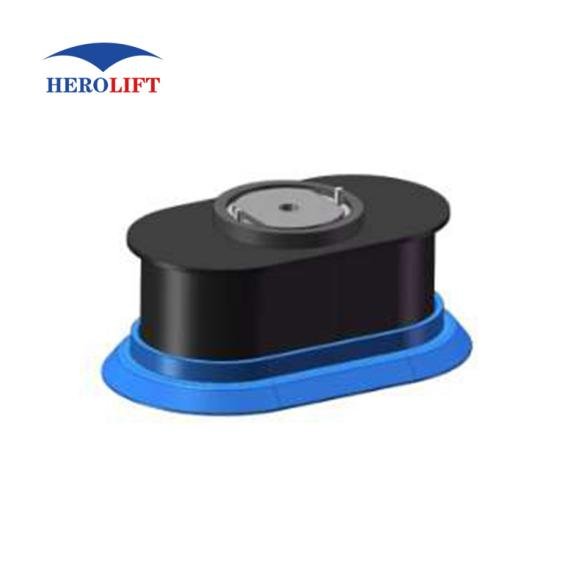

3. Овальные присоски: эффективно используют поглощающую поверхность; Подходят для длинных выпуклых деталей; Вакуумная присоска с увеличенной жесткостью; Маленький размер, большой всасывающий эффект; Используются как плоские и рифленые присоски; Различные материалы присосок; Встроенные конструкции обладают высокой силой захвата (дисковая присоска). Типичная область применения овальных присосок: обработка узких и маленьких деталей, таких как трубные фитинги, геометрические детали, деревянные рейки, оконные рамы, коробки, алюминиевая фольга/термопластические упаковочные изделия.

4. Специальные присоски: они такие же универсальные, как обычные присоски; Особенность материала и формы присоски делает её применимой в специфических областях/предприятиях; Типичная область применения специальных присосок: обработка деталей с особыми свойствами. Например, хрупких, пористых и деформируемых поверхностей.

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SL

SL

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

BE

BE

MK

MK

AZ

AZ

UR

UR

EO

EO

LA

LA

MN

MN

KK

KK