Vacuum forming plastic might not be new to you but did you know that this is also possible with sheet metal? That’s right. Vacuum forming is a unique type of metal forming. Step 1 Heating the metal until it is soft and malleable After that, you mold it and start to vacuum shape the rest into whatever form you like. This process is quite intriguing and can produce some truly inspired results.

Vacuum Forming of Metal

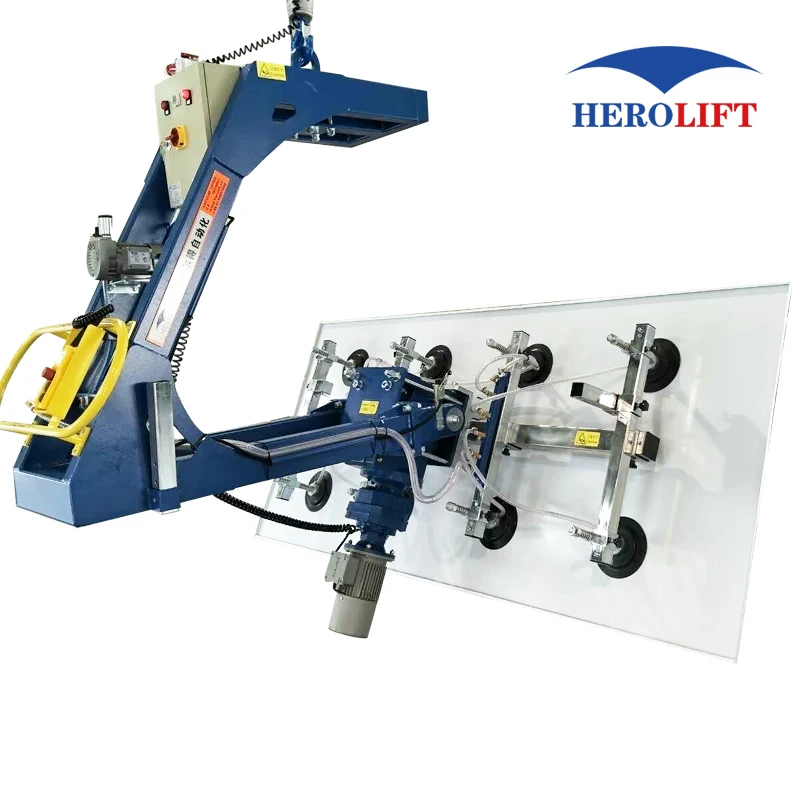

There is that freedom to design when it comes vacuum forming sheet by Herolift any kinds of shapes. In practice, this would involve a 3D model of the desired shape and mold adapted to match that metal sheet exactly. Either in the form of a clay model or you can 3d print one Earlier this week, we had the opportunity to pay a visit with Lasting Concepts for an install of their latest product: these maxillary fascia plates which undergo irreversible deformation under heat and use vacuum assist to form. The vacuum lifting, on the other hand sucks that metal down into to mold and imprints it with desired shape. This allows you to develop various beautiful designs that would be very difficult for other approaches.

Think Outside The Box For Metal Projects

In fact, vacuum forming is not exclusively for large factories and Industries. you could just used it for artsy stuff making cool jewellery or custom car parts. The opportunities are simply endless and can truly be a figment of your imagination. Vacuum forming allows you to produce a more complex shape that would otherwise be tough, if not impossible by hand. For a man who likes to work with metal, it literally was like being plucked from one dimension and flung into another.

Article Why Vacuum Forming for Sheet Metal?

The primary reason for selecting vacuum forming is that it will help in excess of more money savings while increasing efficiency. It is much less expensive than the alternatives to form metal - this a major advantage. In addition, vacuum lifter forming is a quicker process so more parts can be made in less time. This is particularly useful if you are working on a project that needs multiple components. you would get things done faster and more organized.

How to Vacuum Form at Home

So, you may be wondering can sheet metal be vacuum formed at home? Well, yes and no. Vacuum forming operations can be carried out in your own workshop or home, but you will require a few tools and special materials to get started. Materials: Vacuum Handling Trolley former Heat source to warm the metal Yarn Mold Sheet of metal. If you want the metal soft, use a heat gun or put it in an oven. This mold can be made of wood, gypsum or silicone depending on what you have at your disposal.

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SL

SL

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

BE

BE

MK

MK

AZ

AZ

UR

UR

EO

EO

LA

LA

MN

MN

KK

KK