- Overview

- Inquiry

- Related Products

IAD-H080 intelligent hoist is an ergonomic material handling equipment which is composed of servo motor, servo driver, load sensor, limit switch, etc. and controlled by the processor. It has the characteristics of easy operation, high precision, intelligence, controllable speed, safety and reliability. It can improve production efficiency and reduce the risk of industrial injury of operators.

Characteristic ( wellable marking )

1, Max.SWL 300KG

Faster speed: up to 40 meters/minute

More responsive: adjustable acceleration and deceleration

Using an intelligent auxiliary lifting device can effectively cover multiple work units

Use an intelligent auxiliary lifting device to cover a large area of a single work area

Low product damage rate and fast return on investment

Low accident risk

More environmentally friendly (dust and moisture resistant)

Equipped with input/output port function, more intelligent.

| IAD - H080 / IAD - H200 / IAD - H300 / IAD - H600 Intelligent aided lifting equipment technical Specification | ||||

| Maximum lifting weight (loads and tools) (KG) | 80 | 200 | 300 | 600 |

| Maximum lifting speed - manual mode (m / min) | 40 | 30 | 15 | 7.5 |

| Maximum lifting speed - suspension mode (m/min) | 36 | 27 | 13.5 | 1.7 |

| Max. lifting stroke (m) | 3.5 | 3.5 | 3.5 | 1.7 |

| Noise | ≤80dB | ≤80dB | ≤80dB | ≤80dB |

| Main power supply (VAC) | Single phase 220V ± 10% | Single phase 220V ± 10% | Three phase 220V ± 10% | Three phase 220V ± 10% |

| Limit | Hardware limit and software limit | |||

| Available power supply for tools | 24VDC,0.5A | |||

| Control mode | Servo control (Position control) | |||

| Lifting media | Φ 5.0 mm 19strand × 7 wire | Φ 6.5 mm 19strand × 7 wire | ||

| Working environment temperature range | -10~60℃ | |||

| Humidity range of working environment | 0-93% without condensation | |||

| Precision of weight displayed (KG) | ±1% rated load lifting capacity | |||

| Cooling method | Natural wind | Natural wind or forced wind | ||

| Serial No. | Max capacity | 80kg |

| Max lifting speed - manual mode (m/Min) | Max lifting speed - suspension mode (m/Min) | 36 |

| Max lifting height (m) | Main power supply (VAC) | Single-phase 220V ± 10% |

| Maximum current (A) | Tool available power supply | 24VDC,0.5A |

| Lift media | Operating ambient temperature range | 5-55℃ |

| Humidity range of working environment | Limit | Hardware limit, software limit |

| Weight display accuracy (KG) | CE certification | Have |

| Cooling mode | Noise | ≤80dB |

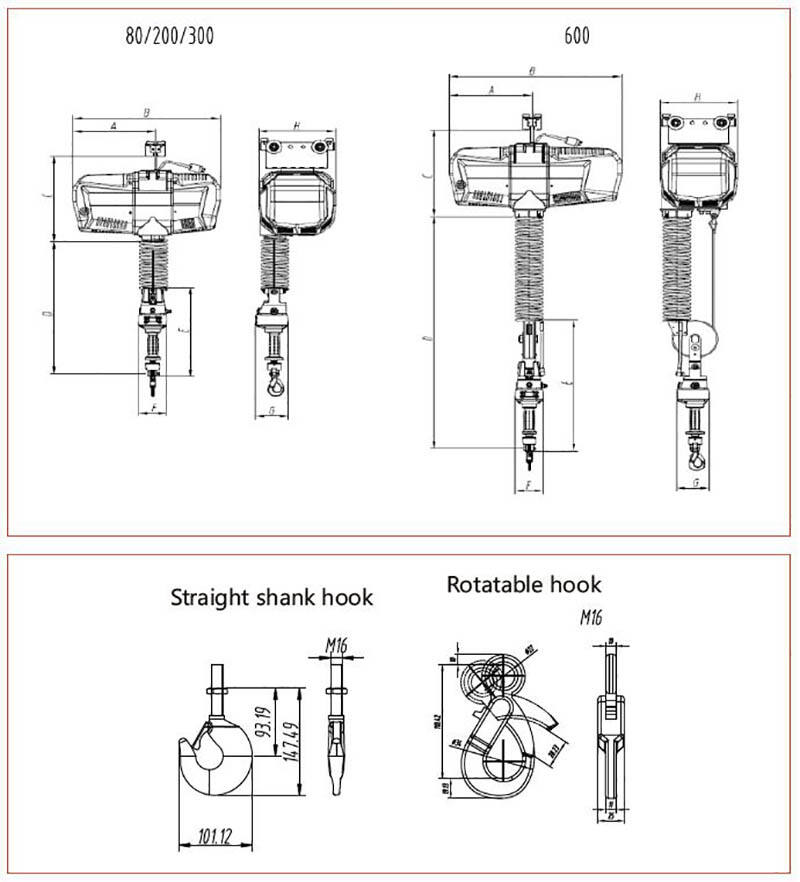

Specification

|

Dimension \Lifting weight |

80 | 200/300 | 600 |

| A | 359 | ||

| B | 639 | 749 | |

| C | 453 | 462 | |

| D | 702 | 1232 | |

| E | 473 | 697 | |

| F | 122 | ||

| G | 142 | ||

| H | 336 | ||

Detail display

|

Main Engine

|

Coaxial sliding handle Gas interface optional matching

|

|

Wireless remote control handle receiver

|

Vertical handle

|

Function

Free speed control: the intelligent auxiliary lifting equipment can move synchronously with the operator, and can move at the speed selected by the operator, which can be fast or slow, so it is very suitable for those operating environments that sometimes need high-speed operation and sometimes need slow and accurate operation in a load.

Ultra-high speed: The lifting speed of intelligent auxiliary lifting equipment can reach 40 meters/minute, which is three times faster than the traditional high-end lifting device on the current market, and it has become a popular fast and accurate lifting device on the current market.

Millimeter-level accuracy: Our intelligent auxiliary lifting equipment can achieve the unparalleled accuracy of lifting speed less than 0.3 m/min, thus ensuring that the operator can carry out necessary precise control when lifting precision, expensive or fragile parts.

Safe choice: Our company's intelligent auxiliary lifting equipment is safe and reliable, greatly reducing the occurrence of industrial accidents.

Anti-bounce technology: this technology can prevent the intelligent auxiliary lifting equipment from shifting or rebounding when the load weight changes, thus reducing the occurrence of potential serious injury accidents.

Load bearing overload protection: intelligent auxiliary lifting equipment will automatically protect when the load exceeds its rated lifting capacity and cannot be lifted.

Operator in place function: the sliding handle of our intelligent auxiliary lifting equipment is equipped with a photoelectric sensor, which will not allow the equipment to run unless the operator gives an operation command.

Suspension mode function: intelligent auxiliary lifting equipment is equipped with "suspension mode" with multiple purposes. Just apply 2 KG force to the load, and the operator can control the load with both hands, and carry out accurate positioning in the whole range.

Suspended unloading mode function: intelligent auxiliary lifting equipment is configured with "suspended unloading mode" specially used for unloading objects. The operator can control the load with both hands to achieve accurate unloading.

High performance-price ratio: intelligent auxiliary lifting equipment technology can greatly improve the production efficiency of your factory by improving the labor efficiency of workers and helping to complete complex operations.

Application :

Auto-industry (parts and vehicle assembly such as engine,

gearbox, instrument board, auto seat, glass)

Finish machining

Machinery manufacturing and processing

Natural gas, oil and other energy industries (valve, drilling tools, etc.)

Repeated high frequency handling work

Parts assembly

Warehouse loading and unloading

Product sub-packaging

Service cooperation

Since its establishment in 2006, our company has served more than 60 industries, exported to more than 60 countries, and established a reliable brand for more than 17 years.

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SL

SL

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

BE

BE

MK

MK

AZ

AZ

UR

UR

EO

EO

LA

LA

MN

MN

KK

KK